- Call Us

- +91 97000 01888

- Mail Us

- a2nlaser@gmail.com

- Location

- Faridabad

Faridabad

Faridabad

Metal laser cutting is a precise way to cut metal. It uses a beam of light to melt or burn metal into the shapes we need. People like metal laser cutting because it is fast and does not waste a lot of metal.

Metal laser cutting in Faridabad provides services to make small and intricate shapes with metal laser cutting. This is because metal laser cutting can get very close to the shape we want, with metal laser cutting often within a tiny bit of the actual size, like a tenth of a millimeter. The best part is that metal laser cutting does all of this without actually touching the metal.

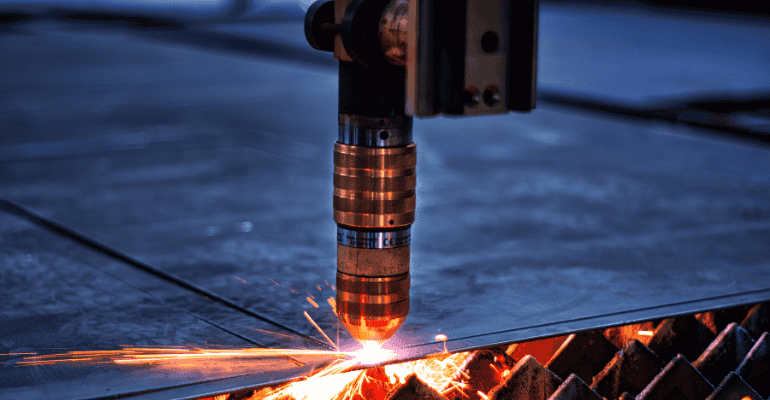

High heat plasma metal cutting work

High-heat plasma metal cutting is a thermal process that uses a high-velocity jet of ionized gas (plasma) at temperatures up to 20,000°C to 30,000°C to melt and blow away conductive metals.

So this is how the process works:

- Arc Initiation: The Arc Initiation process really begins when the electric arc is struck between the electrode, the cathode, and the workpiece, the anode. This is how the Arc Initiation process works.

- Gas Ionization: When you force compressed gas like the air we breathe or gases such as nitrogen or argon through a small nozzle and then add energy to it with an arc, something cool happens.

- Melting and Ejection: This superheated plasma jet melts the metal instantly upon contact, while the high-pressure gas flow simultaneously blows the molten material out of the cut (the "kerf").

Material & Thickness Capabilities for metal laser cutting

Plasma cutting is versatile because it works on any electrically conductive material:

- Common Metals: Laser cutting services in Faridabad are provided for common metals like-Mild steel, stainless steel, aluminum, copper, and brass.

- Thickness Range: Handheld units are usually able to cut things that're up to 38 mm. The handheld units can cut a lot of things. They have a limit of 38 mm. Industrial CNC laser cutting in Faridabad is really good at working with plates. These Industrial CNC systems can handle plates that are up to 150 mm thick, which is about 6 inches.

Plasma vs. laser cutting- What is the difference

The main difference between plasma cutting and laser cutting is the way they melt the metal. Plasma cutting uses hot gas that has electricity in it.

On the other hand, laser cutting uses a very strong beam of light that is focused on one spot. This beam of light is what melts the metal in laser cutting. The technology used in plasma cutting and laser cutting is what sets them apart. Plasma cutting and laser cutting are two methods, and they work in different ways.

Key Differentiators

- Precision and detail: When you need to make intricate parts or engravings, laser cutting is the way to go. This is something that a plasma torch just cannot do because it is too big. Laser cutting is really good at making these cuts, which is why it is so good, for precision and detail.

- Speed by Thickness: When you are dealing with Thick Metal that is thicker than 16 mm Plasma systems are the way to go. They can cut through these plates really fast, and they do a much better job. Thick Metal like this is no problem, for Plasma systems, they can handle it easily. Get the job done quickly.

- Heat-Affected Zone: When you use Plasma, it gets really hot. That heat spreads out over a bigger area. This can make the edges of the material get all warped or hard. On the other hand Lasers do not get as hot, and they do not affect as much of the material.

- Operational Requirements: Systems for metal laser cutting services in Faridabad are sensitive to dirty environments and require specialized maintenance. Plasma cutters are more robust and can easily cut through rusty, painted, or dirty metals that would interfere with a laser beam.