- Call Us

- +91 97000 01888

- Mail Us

- a2nlaser@gmail.com

- Service

- Laser Cutting

- Aluminium Laser Cutting

Aluminium Laser Cutting

Aluminium Laser Cutting

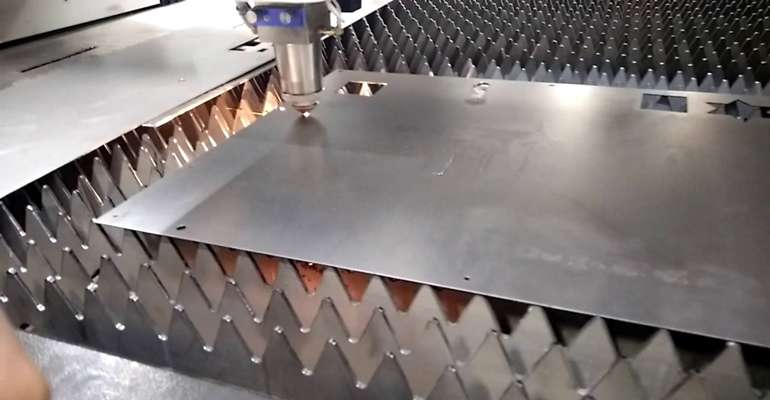

Aluminium laser cutting is a precise way to make things. It uses a laser beam to cut through aluminium sheets and plates. People like this method because it is fast and accurate... The thing is, aluminium is not easy to cut. This is because aluminium is very good at reflecting light, and it can conduct heat well. Aluminium laser cutting is still a choice, even though aluminium is a bit tricky to work with. Aluminium sheets and plates can be cut with a lot of precision using this method.

Aluminium laser cutting- How it works?

The process is simple. It works in a few steps. First, you do one thing. Then something else happens. The whole thing is based on how it works. Therefore, to understand it, you need to know how it works.

Modern systems use Fiber Lasers with a wavelength of 1.064 micrometers, and these Fiber Lasers are absorbed by aluminium a lot better than the old CO2 lasers. Fiber Lasers are good at this because they have a wavelength that aluminium absorbs well. This makes Fiber Lasers more useful for working with aluminium than the older CO2 lasers.

Common Aluminium Grades for Decor

- 5052: People usually use this material for laser cutting. The reason is that 5052 is easy to work with it does not corrode easily. It cuts nicely. 5052 is a choice because 5052 is very flexible and 5052 can withstand corrosion very well.

- 6061: Harder and stronger, often used for structural Mandir frames or furniture legs.

- Anodized Aluminium: You can use a laser to cut Anodized Aluminium laser cutting service. This way, you can make signs that really stand out because the silver Anodized Aluminium shows through the paint. It is a way to make signs with a lot of contrast. The Anodized Aluminium looks good when it shows through the coating on the Anodized Aluminium sheets.

Comparison with Brass

You wanted to know about brass, so I will tell you how it is different when you use it for things you do at home.

- Brass has a nice gold look that people think is fancy, but it gets dirty and old looking after a while. Aluminium is a grey color, like silver, but you can make it look like any other metal if you want to, like brass or something else.

- Cost: Aluminium laser cutting work is usually cheaper than brass. This makes it a good choice for things like wall panels that cover the whole wall or screens that go all around the room. Aluminium is an option when you need to make something big because it does not cost as much as brass.

- Ease of Install: Aluminium is light, so you can usually put up laser-cut panels with just some simple glue or small brackets. If you were using brass, you would probably need wall anchors to hold it up. This makes aluminium a lot easier to work with when it comes to installation. Aluminium is just lighter and easier to handle, which is a plus when you are trying to install large laser-cut aluminium panels.

Aluminium laser cutting for home decoration

Aluminium laser cutting is a way to make things for your home without spending a lot of money. It is an alternative to using brass. People are really using aluminium laser cutting a lot in 2025. They like it for architectural elements.

This is because aluminium laser cutting is 60 percent lighter than brass. That means it is easier to put up on your walls without needing help. You can just use the drywall you have at home. Aluminium laser cutting is a lot lighter. That is why people like it for big projects.

Top 2025 Decor Trends for Aluminium

You wanted to know about brass, so I will tell you how it is different when you use it for things you do at home.

- Shadow Box Art: The silver surface of aluminium is good at reflecting the light from LEDs. A lot of designers are making art that looks like it is floating on the wall by using aluminium panels that are cut with a laser and placed a couple of inches away from the wall with lights that change colours behind them to create a glowing effect. Aluminium is a choice for this kind of art because it works so well with the LED light.

- Anodized Color Palettes: Aluminium laser cutting work is cool because it can be colored in many different ways. It does not have to be one color, like brass, which is usually gold. Aluminium can be made to look like all sorts of things, such as shiny colours or a flat black color or even a color that looks like champagne gold, which is similar to brass but costs less. The Anodized Color Palettes of aluminium are very versatile. That is what makes them so great.