- Call Us

- +91 97000 01888

- Mail Us

- a2nlaser@gmail.com

- Blog

- MS Laser Cutting for Sheet Metal Work

MS Laser Cutting for Sheet Metal Work

MS Laser Cutting for Sheet Metal Work

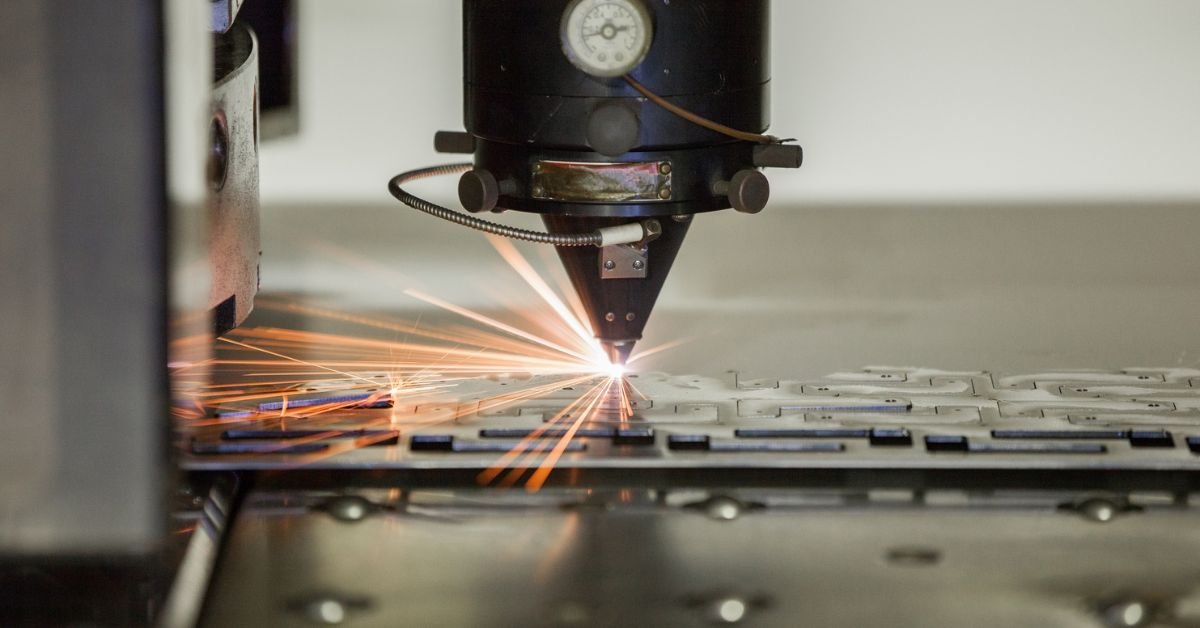

Using a laser to cut metal is a highly precise thermal process where a focused beam melts or vaporizes the material. It is a standard in modern manufacturing for its speed, accuracy, and ability to handle intricate designs.

Types of metals suitable for laser cutting work

Laser cutting is compatible with nearly all industrial metals, though the efficiency and edge quality depend heavily on the metal's thermal conductivity and reflectivity.

Most Common & "Easy" Metals

• Carbon Steel (Mild Steel): This is the metal that people cut with lasers the most. The reason for this is that Carbon Steel absorbs laser energy well. So people like to use Carbon Steel for things, like car parts and building structures.

• Stainless Steel: Valued for its corrosion resistance. Using nitrogen assist gas allows for "clean cutting" with a shiny, oxide-free edge, ideal for medical and food-grade applications.

• Alloy Steel: Most structural and tool steels cut well, though some high-tungsten varieties may produce slag.

Reflective & Conductive Metals (Best for Fiber Lasers)

These materials reflect CO2 laser beams, which can damage the machine. High-power Fiber Lasers are the standard for:

• Aluminum: It is a material that's really lightweight, and it does not corrode easily, but it has one big problem: it gets hot really fast, so you need to use more power to get a consistent cut when you are working with Aluminum.

• Copper is a shiny metal, and it is very good at conducting electricity. People usually cut Copper into shapes that are used to make components and busbars.

• Brass: A copper-zinc alloy that is slightly easier to cut than pure copper but still requires high-power fiber technology to overcome reflectivity.

High-Performance & Specialty Metals

• Titanium: The thing about Titanium is that it reacts easily with things, so people usually use Argon or Nitrogen gas when working with Titanium to stop it from getting damaged at the edges.

• Nickel Alloys are used a lot in the aerospace field because of this. People can cut Nickel Alloys by using methods that involve oxidation and melting. This works well for Nickel Alloys.

• We can use special lasers to cut Gold and Platinum. They are used to make jewelry and other expensive things, like luxury goods.

• Galvanized Steel: Cut similarly to mild steel, but the zinc coating can release fumes and affect edge quality.

Metals to Avoid or Use Caution for Laser Cutting

• Lead: Generally avoided due to the high risk of toxic fumes.

• Beryllium Copper: Dust and fumes from this alloy are extremely hazardous to human health.

• Magnesium: Highly flammable; cutting requires specialized safety protocols to prevent metal fires.

Applications of metal laser cutting in industries

Metal laser cutting is a cornerstone of modern manufacturing, used to produce high-precision components across nearly every major industrial sector. Its ability to create intricate designs with tight tolerances (often ±0.1 mm) without mechanical force makes it indispensable for high-stakes applications.

Key Industrial Sectors

• Automotive Industry: One of the largest users of laser cutting, employing it for high-volume production of car body panels, engine components, chassis parts, and exhaust systems.

• Aerospace and Aviation: Aerospace and Aviation need to use metals like titanium to make parts like the blades that spin in a turbine, the connections for the fuel tank, and the main parts that make up the wing of a plane.

• Medical Technology: laser cutting methods are used to make things like instruments and orthopedic implants. We also need Medical Technology to make devices that go inside our bodies, like stents and pacemakers.

• Electronics & Electrical: Used for the miniaturization of devices, including cutting circuit boards (PCBs), connectors, heat sinks, and protective enclosures for mobile phones and laptops.

• Construction & Architecture: Widely used to fabricate structural steel beams, connection plates, and decorative architectural elements like custom facades and screens.

• Energy Sector: Vital for renewable energy infrastructure, such as cutting plates for solar panels, wind turbine components, and lithium-ion battery parts.

• Shipbuilding & Marine: Employed for cutting thick steel hull panels, bulkheads, and intricate interior fittings that must withstand corrosive environments.

Specialized Applications

• Agricultural Machinery: Fabricating durable parts for tractors, plows, and irrigation systems.

• Fitness Equipment: Precise shaping of metal tubes and sheets for weightlifting racks and treadmill frames.

• Signage & Branding: Creating high-contrast metal signs, engraved logos, and decorative art pieces.

• Rail Transportation: Producing body panels for train coaches and structural chassis members.

Types of lasers for cutting and fabricating metals

The main types of lasers that are used for cutting and fabricating metals include

* Carbon dioxide lasers

* Neodymium lasers

* Fiber lasers

* Direct Diode Lasers

Computer and software-guided movements for precision laser cutting

Computer-guided precision in metal laser cutting is achieved through Computer Numerical Control (CNC). This system acts as the "brain," translating digital designs into micro-movements of the laser head or worktable with tolerances as tight as ±0.01 mm.

The Motion Control System

Precision relies on a "closed-loop" feedback system where the controller constantly compares the actual position of the laser to the programmed coordinates.

• Drive Mechanisms:

Servo Motors are used in high-end machines because they can do things quickly and precisely. The Servo Motors also use something called encoders to get information about where they're what they are doing, and they get this information in real time.

Stepper Motors are really common in machines that people just start with. They move in steps, but they do not have a way to fix their own mistakes like some other motors do.

• Mechanical Rails: The laser moves along linear guideways and is driven by rack and pinion systems (for speed over large areas) or ball screws (for maximum precision and backlash-free motion).

Types of Movements

1. Cutting sheet metal is usually done with a 2D Flatbed Cutting method. This is where the laser cutter moves back and forth along the X and Y axes to cut the metal. It is used for 2D Flatbed Cutting of sheet metal all the time.

2. The 3D robotic cutting thing uses a robot arm to move a laser in lots of different directions so it can cut weird shapes and tubes, and really complicated 3D things from all sorts of angles.

3. Rotary Axis: A specialized motor rotates a cylindrical workpiece (like a pipe) while the laser moves linearly, enabling 360-degree precision cuts.

Software Workflow

• Computer-Aided Design is what CAD stands for. We use Computer-Aided Design programs like AutoCAD. SolidWorks to make the vector blueprint. These Computer-Aided Design programs are really helpful for creating the blueprint.

• Computer-Aided Manufacturing or CAM is really useful. It is a type of software. This software helps to make things. These Computer-Aided Manufacturing software tools take the design we make. Turn it into something called G-code. The G-code is like a set of instructions. It tells the motors of the machine where they need to move. It also tells them how fast they should move. This is really important for Computer-Aided Manufacturing to work properly.

• Nesting Algorithms: These automatically arrange parts on a metal sheet to minimize waste and optimize the cutting path.

Precision Enhancement Features

Height Sensing:

The high-precision heads have sensors that keep a distance from the metal. This distance is always the same, even when the metal sheet is not perfectly flat. The metal sheet can be a little warped. The sensors on the high-precision heads will still keep the right distance. This is what we mean by Height Sensing for these high-precision heads.

Look-Ahead Algorithms:

Advanced controllers "look ahead" at the upcoming path to anticipate sharp corners, slowing down slightly to prevent overshooting and ensure a clean finish.